RCS BDC is designed for independent remote discharge of rock from mine cars into the lump ore charging hopper.

Main purposes of the system:

- improving the safety of process implementation;

- improving the technical and organizational level of operations;

- maintaining technological and organizational processes through the use of integrated control system that meets up-to-date performance, reliability and operability requirements;

- enhancing diagnostics and monitoring functionality during the remote operation of electric locomotives;

- protection of operating personnel and manufacturing equipment in pre-emergency situations using the interlocking functions of the system.

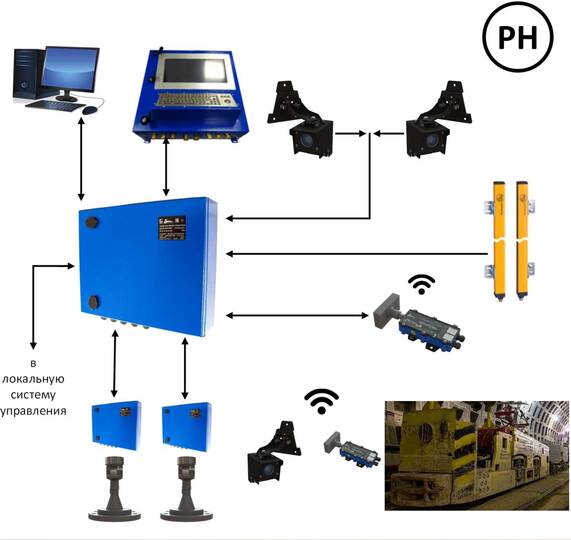

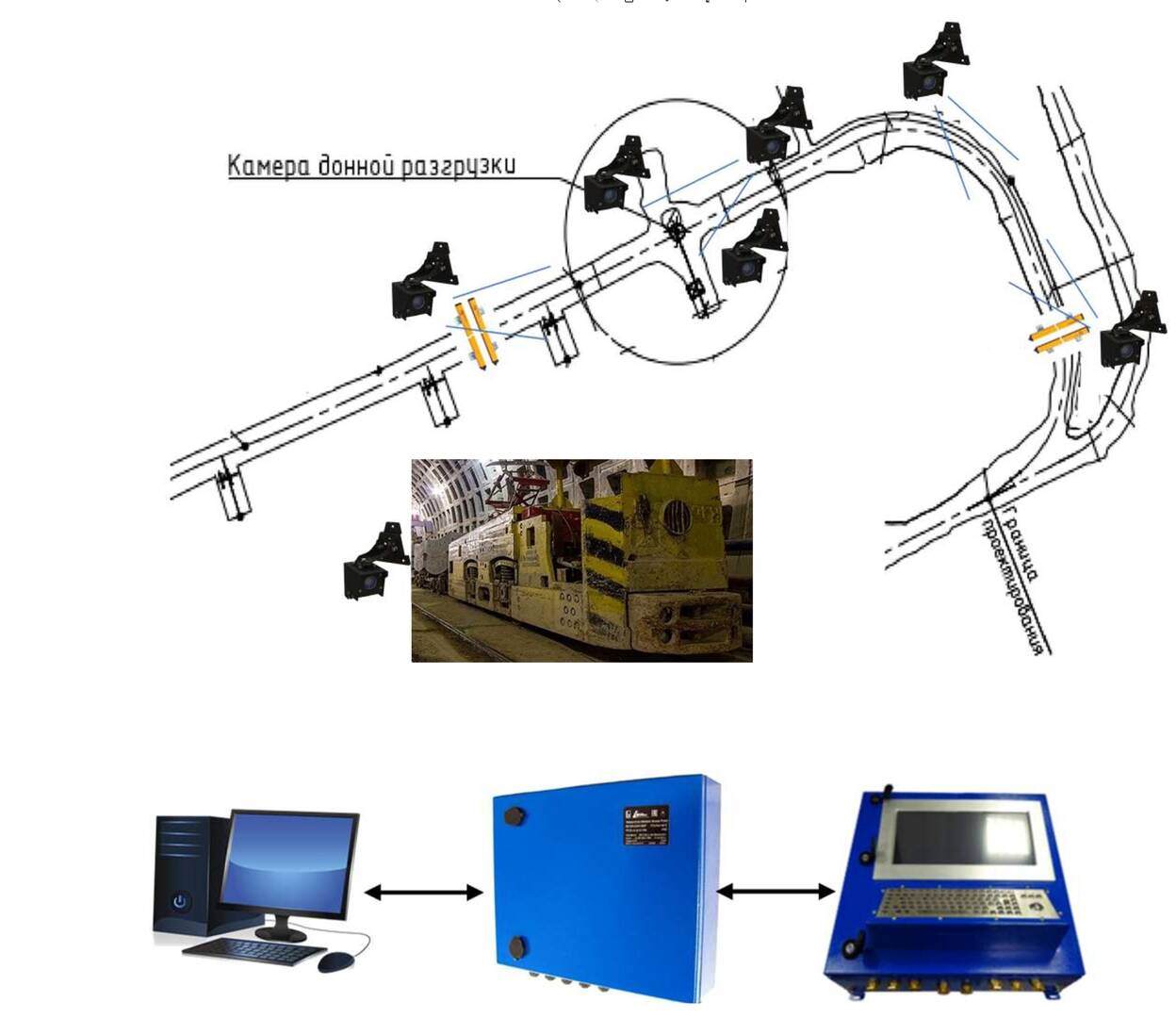

RCS BDC provides control and integration of the following components:

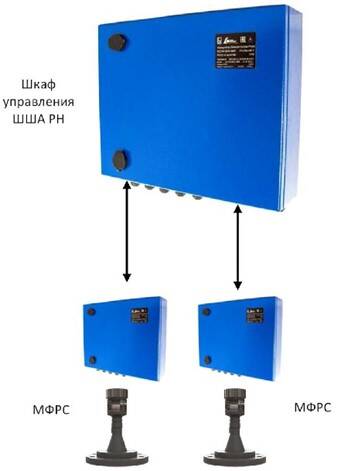

- bottom-discharge station mechanisms

- gate

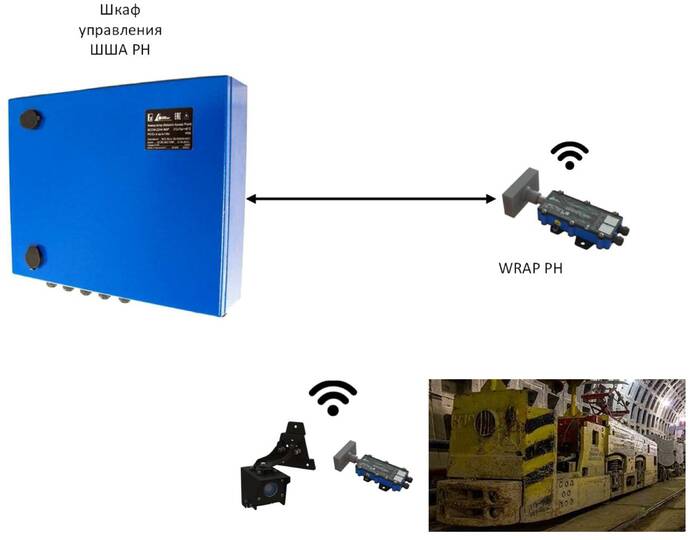

- electric locomotives

- level indicators

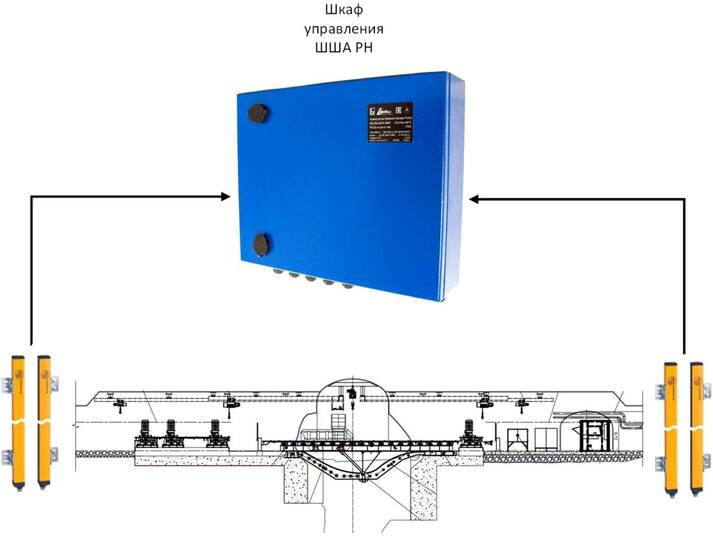

- safety barriers

- video surveillance system

Components of the remote control system for the bottom-discharge chamber: