Dispatching control, safety, monitoring and communication

Personnel and TMM Tracking and Collision Warning System

This system allows to handle different tasks involved with identifying locations (positioning), tracking and registering parameters/status (monitoring), and controlling the traffic of personnel, underground transport, mining equipment, etc.

It is designed for operation in underground shafts, mines and associated surface structures, including gas and dust hazardous areas as consistent with the product explosion proof mark and operating conditions described in the Technical Regulations of the Customs Union 012/2011 “On equipment safety for operation in explosion hazardous areas”. PTTCWS is used in accordance with the following federal rules and regulations applicable to industrial safety: “Safety regulations applicable to mining operations and processing solid commercial minerals” and “Safety regulations applicable to coal mines”.

PTTCWS ensures the compliance with requirements of paras. 6.3.9 and 8 of GOST R 51522.1-2011 “MULTIFUNCTIONAL SAFETY SYSTEMS FOR COAL MINES. General specifications” in terms of the regulations applicable to the personnel location monitoring and identification subsystem used in mine workings (positioning).

The system can be used for identifying the current location of miners and vehicles in normal and emergency operation conditions. In case of emergencies or performing rescue operations, the System is used to identify the latest recorded location of miners.

The system provides the following:

- continuous positioning of personnel (including the personnel onboard vehicles or mobile equipment) and mining machines including visual display on a scale diagram of the mine with minimum +/- 5 m resolution inside the central control room

- zone-based positioning in mine workings

- manual (awareness control) acknowledgement of receiving a warning signal from the dispatcher and transmitting an emergency warning signal to the dispatcher by the miner in underground shafts, mines and associated surface structures

- transmitting an emergency warning signal to personal miners’ radio units when identifying tags within the coverage area of the readers

- monitoring, tracking and warning subsystems are kept operational for at least 16 hours in case of normal supply source outage (included in the design)

- developing and automatic monitoring of personnel and machine routes

- archiving data on tag carrier location and movement at any specific time

- password protection against unauthorized access to System control and operating mode switching

- data collection by reading devices (RM485- 802.15.4 radio modules) in case of losing communication signal with the System server and subsequent transmission of collected data when the communication is reestablished

- automatic detection of personnel that failed to escape from the mine in a timely manner

- continuous performance diagnostics of the system equipment

- system expandability: introducing new technical devices without modifying system hardware while developing mine workings. Real-time scaling and structure configuration in mine workings

- integration with the following systems:

- corporate pass entry system

- system for finding people trapped under debris

- proximity and collision warning system

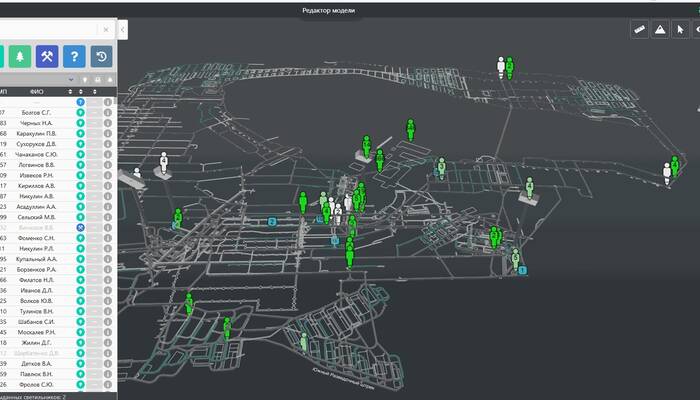

PTTCWS model

- 3D model of the mine for visual monitoring purposes

- Real-time display of current or latest registered item

- Positioning of personnel inside the cage or onboard vehicles

- Individual or group personnel warning and acknowledgement

- Monitoring of working hours, lamp distribution and job order execution

- Transmission and control of data collected by portable gas analyzers

- Low power consumption of system components

The following functional subsystems form part of the system structure:

- IEEE 802.3 Wi-Fi communication subsystem (providing mobile communication and access to the local area network in mine workings for tablets and smartphones connected to WiFi through the implementation of the IP communication system)

- Underground transport traffic control subsystem and warning vehicle operators of dangerous proximity to miners and other vehicles

- Video monitoring subsystem

- Subsystem for monitoring underground transport and extraction systems (radio controllers for collecting and transmitting additional data from technical devices, sensors, etc. Monitoring parameters/status of underground transport and mining equipment, automated tracking of mined rock conveyed by underground transport)

- Positioning subsystem – positioning and data reading from the following devices:с:

- personal tags;

- transport tags;

- monitoring data collection tags;

- radio buttons;

- portable gas analyzers.

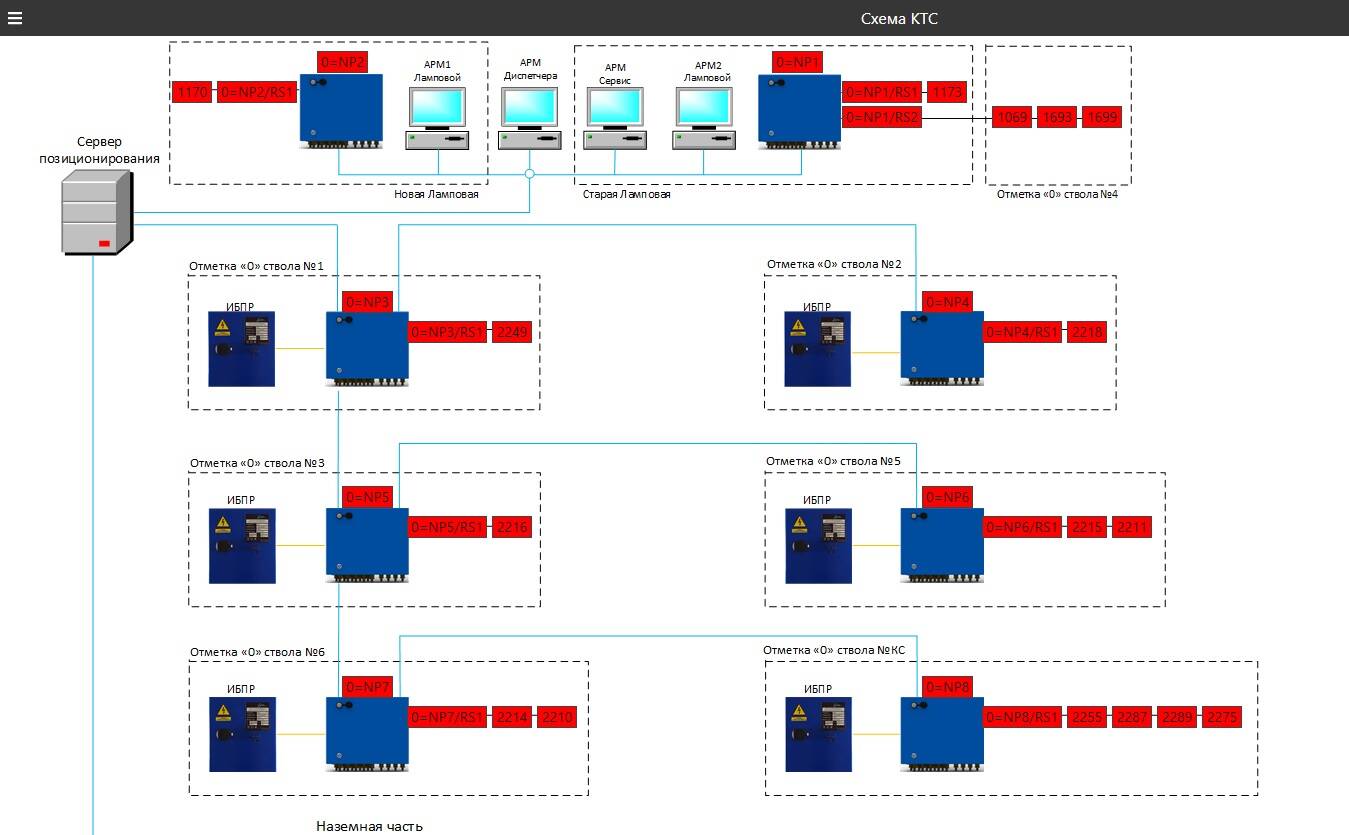

- Connecting all the subsystems to the backbone data network of the mine

Dispatcher’s AWS functions

- Displaying detailed information on traceable items (department, job position, affiliation with contracting organization, etc.)

- Generating reports on movement of personnel and transport

- Generating timesheets

- Possibility of emergency call/signal transmission to the dispatcher

- Keeping system event and emergency logs

- Hardware package monitoring

- Archiving positioning data for at least 90 days